Frequently Asked Questions & Other Resources

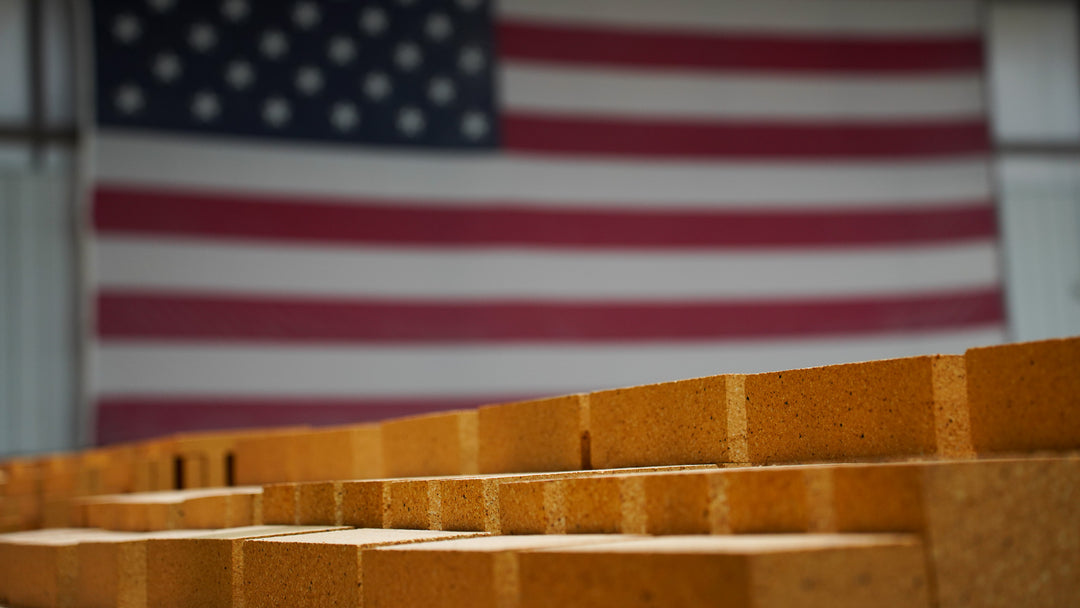

Here you’ll find a comprehensive resource designed to answer all your questions about Alsey firebrick and firebrick stain products. We’ve gathered a collection of Q&A videos that provide in-depth insights into product features, application techniques, and maintenance tips. Whether you’re a seasoned professional or new to using our products, this page addresses the most commonly asked questions from our customers. We’re committed to helping you get the most out of our firebrick solutions—explore the FAQs below to find the information you need.

Firebrick Q&A Video

Firebrick FAQs

We suggest a rate of 1°F per minute to 212°F with a 1-hour hold at 212°F. Continue heating at a rate of 1°F per minute to 1000°F, then increase the rate to no more than 5°F per minute to operating temperature.

The heat-up schedule should consider the physical states of silica more than alumina. Alumina has no changes at temperatures between 0°F - 2910°F. Silica (quartz) has two significant changes in physical state in this range. One around 1060°F where low quartz transforms to high quartz with a 5% increase in volume. Another around 1600°F when high quartz transforms to low tridymite with a 12% increase in volume. This means there is the possibility of lining walls to buckle and/or spall as you heat up. We recommend every installation to have a 1/4” minimum expansion gap every 4’ when heating to 2000°F (fireplace installations). When operating closer to 3000°F, we recommend a 3/8” minimum expansion gap every 4’. Also, do not exceed 10°F per minute. Most gas fire applications have an immediate jump to 500°F or more; this should be avoided in the initial bake out by using a lower BTU heat source.

Yes, refer to Smithfield Unbranded Medium Duty Firebrick to find a listing of additional fireplace/wood stove sizes that are available in High-Duty. If further shapes/sizes are needed, please see Jet D.P. High Duty for 100+ options.

Alsey firebrick conforms to all applicable building codes, including the International Code Council, the International Residential Building Code, and the National Fire Protection Association.

The standard color for Alsey firebrick is light buff, although there may be slight differences in color due to the natural variations of the raw materials. Alsey firebrick does not come in other colors but can be stained using Alsey Firebrick Stain and Color Enhancer.

This product has not been rated nor is it regulated by the FDA; however, our firebricks are currently being utilized in installations as a cooking surface. When constructing a floor/cooking surface, our larger firebrick has become more popular than the traditional 9” straight firebrick.

Yes. However, your firebrick will have better longevity if it is covered/protected from the elements.

Alsey Hi-Cast 60 has a higher service temperature rating and is stronger. (See respective data sheets).

Firebrick Stain Q&A Video

Firebrick Stain FAQs

The standard color for Alsey firebrick is light buff, although there may be slight differences in color due to the natural variations of the raw materials. Alsey firebrick does not come in other colors but can be stained using Alsey Firebrick Stain and Color Enhancer.

No, Alsey Firebrick Stain and Color Enhancer is specifically formulated to coat Alsey Firebrick.

After laying up the brick, use a painter’s brush to individually paint each brick. For a monochromatic look for the bricks and mortar, use a large sponge to apply it over the entire firebox.

Yes, but please note that when wiping mortar joints, the transfer of color will occur.

Yes, Alsey stains may be mixed to create custom colors. However, do not mix any other products or additives with our stain.

One quart of Alsey Firebrick Stain and Color Enhancer is enough to accomplish 2 coats on approximately 75-100 firebricks.

Alsey Firebrick Stain and Color Enhancer is water-soluble.

Castable, Monolithic, & Other FAQs

No, Alsey Hi-Cast Refractory Castable is intended for casting pieces or patching large areas.

Alsey Hi-Cast 60 has a higher service temperature rating and is stronger. (See respective data sheets).

This product has not been rated nor is it regulated by the FDA. We do not recommend it.

Alsey Hi-Cast Refractory Castables can be used for domes, walls, and floors for pizza ovens/bread ovens (refer to cooking surface note above), wood-stove inserts, fireplace inserts, etc.

We recommend 1/16 - 1/8”; definitely no greater than 1/4”. At 1/4”, you could experience shrinkage and cracking.

High humidity and cold temperatures can delay set-up beyond 5 days. In this case, we suggest a torpedo heater with a Visqueen hood to drive off moisture to allow the mortar to set up. The use of additives could also slow set-up or compromise set-up entirely.

No, do not use it in outside installations. This mortar is water soluble and will eventually erode if exposed to rain or snowmelt. Please use a hydraulically setting mortar for outdoor applications.

Yes, Alsey Smithfield Air-Set Refractory Mortar conforms to all applicable building codes, including the International Code Council, the International Residential Building Code, and the National Fire Protection Association.

Yes, Flue-Set is a hydraulically setting mortar that is non-water soluble.

The liquid on top of the mortar is Sodium Silicate that comes out due to normal settling and shipping of the product. This Sodium Silicate can be stirred back into the mortar immediately, can be poured off into a container to be added in after stirring, or can be poured off completely and not utilized. If you decide to pour off the excess, there is still enough Sodium Silicate in the mortar to be effective. Most people pour it off and save it in order to add some back in to get the mortar to the consistency they desire.

The addition of Citric Acid or .10 lb of baking soda to 100 lbs of Flue-Set will retard set-up.

Start with 1/2 of the material and mix it with 1/2 of the water. Add extra as needed. Do not retemper!

Mortar should be utilized at temperatures above 32°F, and temperatures should not be allowed to fall below that before the mortar is able to set up.

1” maximum.

Yes, please note that firebrick must be very clean (all soot must be removed) or Flue-Set will not stick.

Flue-Set sets up unusually quickly and will begin to set up within 15 minutes of mixing. (The addition of Citric Acid or .10 lb of baking soda to 100 lbs of Flue-Set will retard set-up and allow more time to construct.) A soft Flue-Set joint is usually caused by retempering. Flue-Set must NOT be retempered; this ruins the mortar and it will not set up properly. To repair a crumbling and degraded joint that has been retempered, grind or rake out joints with a screwdriver 3/4” to 1” deep and repoint with Flue-Set that has been mixed properly.

20 mesh dry milled plastic fire clay.

No, there is no setting agent in Alsey Dry Milled Fire Clay.

Old-time masons have added Portland and sand to create a mortar. This does not comply with building codes (see fireplace bulletin). Currently, it is used as a loose insulating layer to set bricks in, it is used extensively in foundry and pottery work, and it is used in manufacturing processes for other products.

Residential Products

Explore our premium residential products, crafted to bring exceptional durability and style to your home projects.

From high-temperature firebricks to versatile mortars and stains, our solutions are designed to enhance both the performance and aesthetics of your fireplaces, ovens, and more.

Industrial Products

Discover our high-performance industrial products, expertly crafted to withstand the toughest high-temperature environments.

Explore our robust range of firebricks, mortars, and custom solutions designed to elevate your industrial projects with exceptional durability and reliability.

Our Promise To You

At Alsey Refractories Co., we are committed to delivering the highest quality refractory products and exceptional customer service. Our promise is to provide durable, reliable, and efficient solutions for all your high-temperature needs. We stand by our products, ensuring they meet the rigorous demands of your projects while offering competitive pricing and a seamless customer experience. Your success is our top priority